Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

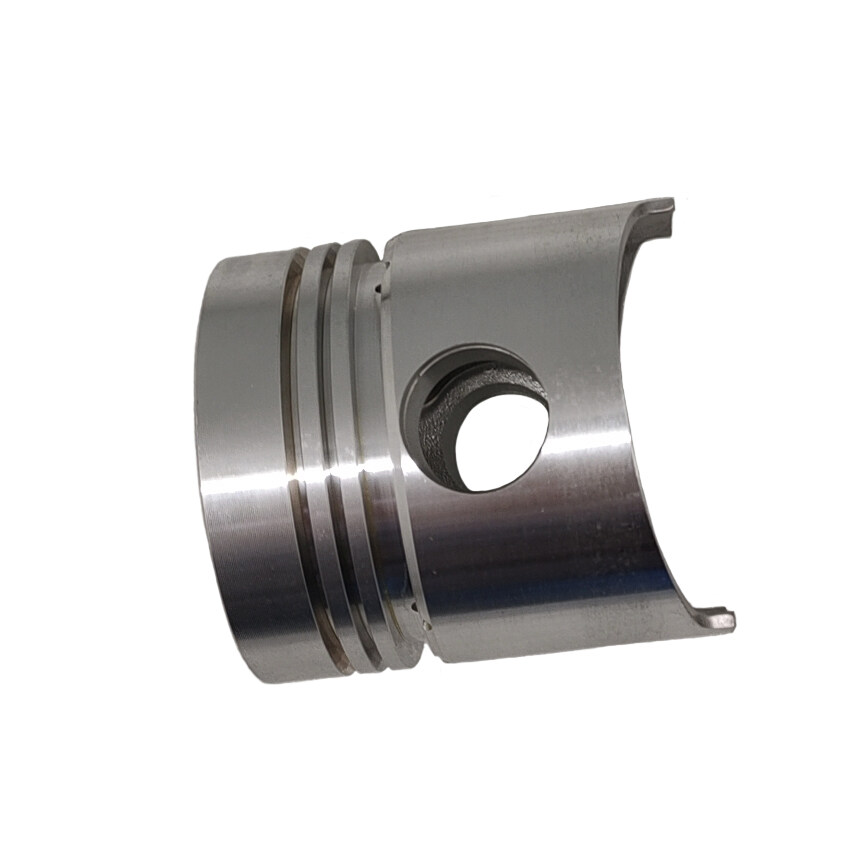

6 Cylinder 6640 Diesel Engine Piston

The 6-Cylinder 6640 Diesel Engine typically uses pistons that are essential components in the engine's internal combustion process. The piston's role is to move up and down within the engine cylinder, creating the necessary compression and power generation

Material and Construction: Diesel engine pistons are usually made of high-strength materials, such as aluminum alloy, steel, or cast iron, to withstand the high temperatures and pressures generated during combustion. They are often heat-treated to improve durability.

Ring Grooves: The piston contains grooves for piston rings. These rings are responsible for sealing the gap between the piston and the cylinder walls, preventing the escape of combustion gases into the crankcase and maintaining proper compression.

Crown: The top of the piston, known as the piston crown, is designed to withstand extreme heat and pressure. It is in direct contact with the high-temperature combustion process and must be heat-resistant to avoid damage.

Skirt: The piston's skirt is the lower portion that makes contact with the cylinder walls. It helps guide the piston's movement and provides stability during the engine's operation.

Wrist Pin or Piston Pin: The wrist pin, also known as the piston pin, connects the piston to the connecting rod. It allows the piston to pivot and transfer the linear motion of the connecting rod into the rotary motion of the crankshaft.

Cooling Features: Some diesel engine pistons incorporate cooling features, such as oil jets or internal cooling channels, to manage the piston's temperature and prevent overheating.

Balanced Weight: Properly balanced piston design ensures that the reciprocating mass is evenly distributed, reducing vibrations and minimizing wear and tear on the engine components.

6 Cylinder 6640 Diesel Engine Piston Product Parameter:

|

Product Name |

Engine Piston |

|

Application |

Diesel Engine Parts |

|

Engine Number |

6640 |

|

Size |

STD |

|

OEM Number |

87802372 |

|

Condition |

100% Brand-new |

|

No. of Cyl. |

6 |

|

Warranty |

6 Months |

|

Bore Diameter |

102.0mm |

|

Payment Way |

T/T, L/C, Paypal, Western Union, UPS |

|

Car Model |

Customized |

|

Packing |

Neutral Packing |

Why Choose Us?

- We have researched and developed the engine parts with more than 10 years, so we have great ability to support you the parts with high quality and our best service;

- We are from factory, therefore, we can support you with reasonable price to make you earn more money by reducing the cost, between you and us, there is no one to make a price difference;

- We can give you the right time, such as delivery time or lead time, so that you can well predict the time to make your products be arrived on time so as to make you have long-term cooperation with you customers. And we also want to have a long-term relationship with you, so please trust us, we will try our best to make you satisfy.

Product Description

1.Low weight and high efficiency.

2.It is more flexible and reliable.

3.It required less maintenance.

4.It is easy to manufacture.

5.The power to weight ratio is high.

6.It generates extremely low vibration because there are no working parts in contact with each other.

7.The lack of any rotary elements (such as a crankshaft) makes it fast to start and stop.

Product Functions

Pistons play a vital role in an automobile engine including the spark ignition gasoline engine and compression ignition diesel engine. These two internal combustion engine process is different but they utilize piston for their processes. Below are the functions of the piston on automobile engine:

1.The major function of piston is to transfer the force output of a small gas explosion in the cylinder to a crankshaft. This provides rotational momentum to a flywheel.

2.It moves forward so that gases can be compressed and explosion can occur for the backward movement.

3.The piston contains a pin called piston pin, it allows the gas in the chamber from escaping.

4.A connecting rod attached to the piston’s bottom allows the mechanical work to be transferred.

5.Pistons help to carry the air-fuel mixture within the period of the combustion cycle.

6.Pistons aid the control of oil flow in the cylinder walls using the oil control ring.

Product Working Principle

Asking how a piston work, you will be exposed to the entire working principle of the internal combustion engine. This is because piston does the major work during the four-stroke cycle.

Just as earlier mentioned, an internal combustion engine is of two types and they work in two different manners. One of it work with a spark plug, hence it’s named “spark ignition engine” and the other “compression ignition engine”. Their working is quite different.

Product Material

Cast iron is the earliest material used for making piston. However modern engine benefits from lighter materials for the engine balancing. Good pistons must be able to resist the engine’s combustion temperatures. Alloys such as Y alloys and hiduminium are specifically used to obtain such properties.

Pistons are made from aluminium alloys with a casting process. Some pistons used in racing vehicles requires better strength and fatigue life which is why they are forged.

Billet pistons are also used in racing engines because they do not rely on the size and architecture of available forgings, making the design to change at dying minutes. Although it’s not commonly visible with the naked eye.